Engineering connectivity that meets modern demands

Fiber optics has become the clear choice for designers and integrators who need to move more data — farther, faster, and with higher integrity.

Let’s look at what’s driving the shift:

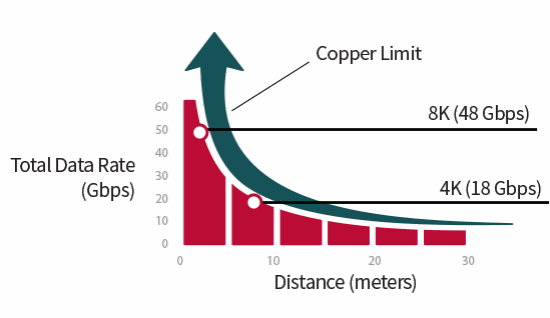

• 8K & Real-Time Video

An uncompressed 8K 60Hz video stream can exceed 48 Gbps, which exceeds the limits of most copper-based video interfaces. Fiber handles these data rates with zero compression and zero degradation, even over long distances.

• AI & High-Performance Computing (HPC)

AI workloads rely on massive volumes of real-time data exchange between GPUs, FPGAs, and memory systems. Interconnects must support low latency, high bandwidth, and tight synchronization to avoid bottlenecks.

• Machine Vision & Distributed Camera Systems

High-resolution sensors (often 12 MP and above) operating at fast frame rates generate gigabits of data per second — especially when deployed across large facilities. Fiber delivers the distance, speed, and EMI immunity required for clean, synchronized data acquisition.