Introduction

The world of fiber optics has a reputation for being complicated and confusing. But not all of that mystique is warranted, especially when it comes to understanding cable types and applications. In this blog, we’ll bust some myths about fiber optic cables—and hopefully convince you that they’re more than just a bunch of glass threads inside an armored jacket!

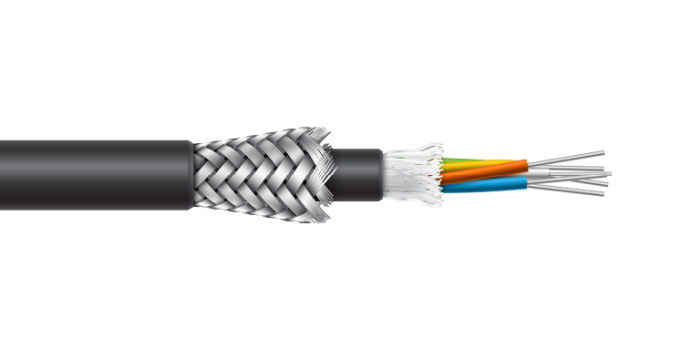

Fiber optic cables are tough and durable

You may think that fiber optics are delicate and cannot withstand tough environments. However, the reality is that these cables can be used in a variety of applications where they are subjected to harsh conditions like temperature variations and exposure to moisture.

In fact, they are durable enough to be used outdoors or even in space! For example, you might have seen them installed on utility poles or inside homes as part of your home internet connection. Other than serving as an alternative technology for transmitting data over long distances; fiber optic cables can also be used in various industries such as the automotive industry, the aviation industry etc., where conventional copper cables would fail due to their low tolerance levels against electromagnetic interference or high electrical noise.

Fiber cables can be used in many different types of applications

Optical cables are used in a wide variety of applications. They provide high bandwidth and long distance transmission capabilities. This make them ideal for a number of applications such as:

- Aerospace industry

- Industrial markets

- Automotive industry

- Oil and gas industry

- Defense sector (military)

In addition to these industries, fiber optic cables are also being used by energy companies for remote metering, pipeline monitoring, electrical substations, and data center connectivity. The medical field has also been using fiber optics for years due to the low noise properties and high data rates needed for high definition video in operating rooms.

There is a cable and termination solution for every environment

You might be thinking that fiber optic cables are too delicate for the field. But this couldn’t be further from the truth! There is a termination solution for every environment—wet or dry, they can handle anything. This is due to the ruggedness and durability of fiber optic cables and connectors. They have been designed to withstand harsh environments, such as extreme temperatures and difficult-to-access locations like oil rigs or military installations. And field termination is fast, easy, and very feasible. In many cases, it is just as fast as terminating copper cables.

Wet or dry, hot or cold, fiber optic cables can handle anything

Don’t let the fact that fiber optic cables are made of glass confuse you. The glass fiber is inside a jacketed cladding, which can be waterproof or even withstand extremely high temperatures or pressures. This means that fiber cables can be used in wet environments, high temperature locations, or other rugged applications. The specialized higher quality of materials for harsher environments are just a specification that needs to be included when choosing the right fiber cables for the system solution.

Different fibers can handle different pull strengths

While it is true that fiber optic cables are designed to be used in different applications, this does not mean that all fiber optic cables have the same pull strength. In fact, there are a variety of fibers available for use with different cables, as well as several ways to install them. Fiber optic cables are designed to withstand different pull strengths based on their type and intended application. For example, plenum pull strength ratings are 30lb+, and armored fiber can have pull ratings of 100lb+.

Each type of fiber cable comes with its own unique strength rating so you know exactly how much pull stress it can take before breaking. Typically fiber cables can withstand between 6 and 20 pounds during installation and in the operational configuration. Therefore, if you were planning on using a cable in an industrial environment where cable tension would be high or regularly changing, you would need to choose a different fiber than if the fiber cable were to be installed in a cable tray with virtually no tension.

Field termination is quick and easy

You don’t need to be a pro to terminate fiber optic cables. The process is quick and easy, and when you’re done, you have a durable product that can be used in many environments. Here are some things to keep in mind as you get started:

- Make sure your tools are properly prepared for the job ahead of time

- Don’t underestimate the importance of using appropriate termination components

- Many connector manufacturers offer field termination kits that provide everything you need

To see just how fast it is to terminate fiber, check out this video of our very own engineer terminating fiber in under 43 seconds!

Conclusion

As you can see, fiber optic cables are very durable and versatile. If you’re looking to include fiber optic cables in your next project, you may have heard some myths about their strength and durability that just aren’t true. They can handle a variety of environments and conditions, making them an ideal choice for many different applications. These myths about fiber optic cables will make you reconsider your next cable installation project. There is a fiber cable solution for nearly every environment!