These days, it seems like just about everything is made overseas. This has become even more apparent with the international shipping delays that consumers and businesses have faced over the past two years. Why do so many companies manufacture outside of the United States? One of the biggest factors is that it is less expensive, since labor costs can be up to 10 times cheaper. This is why most optoelectronic products are made overseas. However, this then requires companies to depend on the timelines and quality control of an overseas company. Additionally, quality control must be monitored remotely, which can be extremely difficult for high-quality, high-performance components. And if there is a quality problem, it is much more difficult to track down the root cause and implement a solution.

However, here at Inneos, we have worked to streamline our designs and automate assembly processes so that we can keep our manufacturing assembly right here in the USA. This allows us to manage the production timelines and the quality control processes, which are critical for producing high-quality, high-performance fiber optic subsystems.

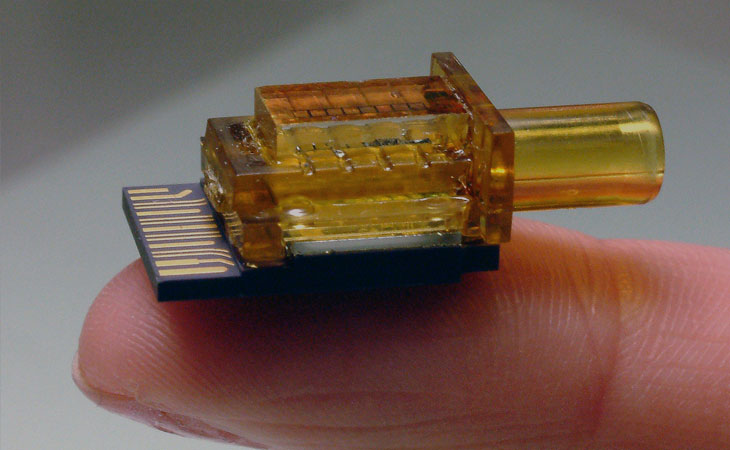

How do we do this? We have looked at every step of the process — from design to manufacturing equipment to assembly processes — to find ways to improve the throughput and yields. We start with engineering designs that minimize touch time in assembly. With 20 years of experience manufacturing optical subsystems, we can design for manufacturing and fit within our optimized assembly processes. This is particularly important for us because our patented wavelength division multiplexing (WDM) optical subassemblies have up to six different optical channels in each optic, which requires a number of precision optical components and different lasers for each channel.

We are proud to say that our VCSELs are made in the USA. We design, manufacture and test our devices on-shore, with capabilities to support WDM wavelengths from 850nm all the way up through 1000nm. Our multimode VCSELs were originally designed for high-performance, high-reliability aerospace applications. That mindset is evident in the quality control of the entire design and manufacturing process. With over 20 years of experience in VCSEL manufacturing, we have components that are suitable for a wide range of applications, including aerospace, medical, automotive, and industrial solutions.

When it comes to optical subassembly (OSA) design, we leverage our vast experience in WDM optics. Inneos was one of the early pioneers of VCSEL-based CWDM in the early 2000’s, and we have been improving on these optical designs and assembly processes ever since. Our optical design uses multilayer dielectric filters to separate out each wavelength channel in a custom-designed optic that is manufactured by Molex, another US company. The filters are designed with tight tolerances so that we can optimize the performance of each optical channel in the device.

We have also gone to extraordinary lengths to use the optimal epoxies for these assemblies. Most people think that a glue is just a glue… but not when it comes to precision optical subassemblies! In the case of our optic design, the epoxies need to have specific thermal performance (because they will expand and contract just like any other material) and even specific optical performance because the epoxy is actually in the optical path.

Our design engineers have tested many different epoxies over the years to evaluate how they perform with the specific wavelength channels in our optic. We have chosen the appropriate epoxies and developed the systems to optimize our assembly processes for the critical optical components.

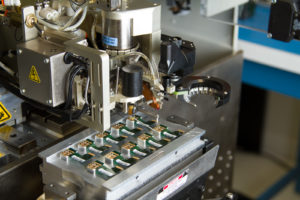

We are also able to manufacture here in the USA using tools made by other American companies, such as Palomar Technologies. Using high-performance precision tools that are designed to be upgradable has allowed us to continue to stay at the forefront of technology. For example, the Palomar 6500 die bonder has been a key tool that enables our precision assembly process. The WDM optical subsystem has up to six different VCSELs and photodetectors that must be placed with extreme accuracy so that all channels couple uniformly into the optic through the multiplexer.

Inneos chose the Palomar 6500 because it allows us to place all of the different VCSEL and photodetector die within a few microns of accuracy with outstanding repeatability. This is no small feat given that the tool must move to 6 different places to pick die and then move back to the assembly with a tight tolerance. With Palomar’s support over the years, we have been able to maintain and improve the process so that this same tool has transitioned nearly seamlessly with each Inneos OSA product generation. The Palomar 6500 die bonder is one key piece of equipment that allows the highly automated assembly that enables Inneos to keep manufacturing here in the USA, where we can assure our commitment to quality and performance.

We have also developed proprietary processes that allow us to quickly perform the optical alignment of six different channels in our WDM optical subassembly, which allows our assembly technicians to optimize their time and maximize throughput at the optical alignment stage of the process. This is a critical process in the assembly of the Inneos optic because our customers expect uniform performance across all channels within each subsystem, and also a high degree of uniformity across many manufacturing lots.

We have even considered the materials and process of the final step for our module products: packaging! With the help of US supplier and packaging design expert Stephen Gould, we created a fully-recyclable box with a sleek design that allows for fast, streamlined final product packaging.

Inneos has developed and maintains a high-throughput, high-quality optoelectronics assembly line in the US for high-performance OSAs, modules, and fiber optic subsystems. Our VCSEL components are also made in the USA with all design, fabrication, and testing done right here on-shore. We continually strive to advance WDM technology and fiber optic system performance while maintaining the quality control and service our customers have come to expect. Inneos is taking connectivity to the next level, right here in the USA.