Engineering Connectivity that Meets Modern Demands

Fiber optics has become the clear choice for designers and integrators who need to move more data with higher integrity.

Let’s look at what’s driving the shift:

- Machine Vision & Distributed Camera Systems

High-resolution sensors (often 12 MP and above) operating at fast frame rates generate gigabits of data per second — especially when deployed across large facilities. Fiber delivers the distance, speed, and EMI immunity required for clean, synchronized data acquisition over a small, lightweight, flexible cable. - AI & High-Performance Computing (HPC)

AI workloads rely on massive volumes of real-time data exchange between GPUs, FPGAs, and memory systems. Interconnects must support low latency, high bandwidth, and tight synchronization to avoid bottlenecks. - 8K & Real-Time Video

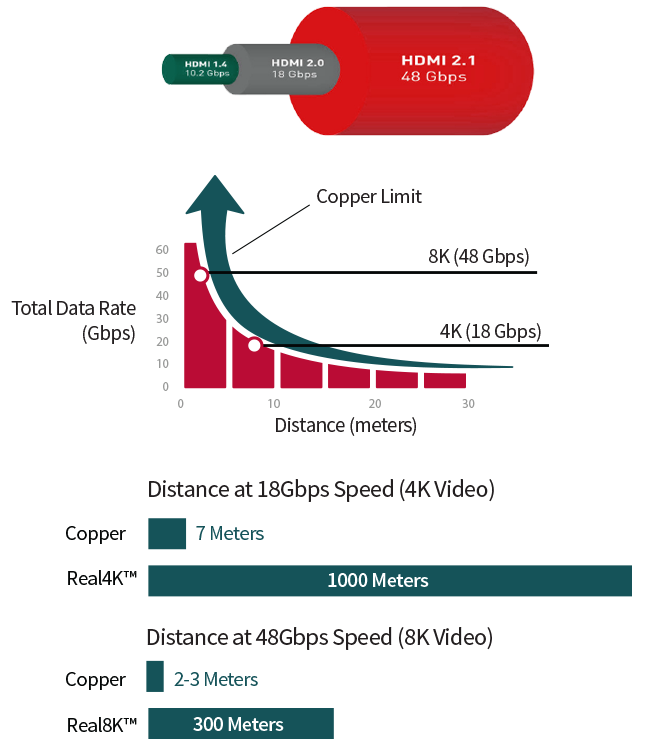

An uncompressed 8K 60Hz video stream can exceed 48 Gbps, which exceeds the limits of most copper-based video interfaces. Fiber handles these data rates with zero compression and zero degradation, even over long distances.

As systems evolve to handle more data, more complexity, and more integration, the limitations of traditional copper interconnects are becoming harder to ignore. Whether you’re transmitting uncompressed video, routing signals through electrically noisy environments, or designing platforms where space and weight are at a premium, fiber optics offers clear and compelling advantages. Fiber isn’t just a high-performance alternative — it’s becoming the smarter default for modern system design.

Copper is Hitting Its Limits

Copper interconnects are simple, familiar, and effective — but only up to a point. As data rates increase and EMI sensitivity of the system increases, copper struggles to keep up:

- EMI susceptibility means copper often requires shielding, isolation, or re-clocking to preserve signal integrity

- Crosstalk and ground loops can introduce intermittent or hard-to-trace failures

- Cable bulk and weight increase quickly with speed and shielding requirements

- Signal degradation over distance makes it difficult to support high-resolution video (like 4K or 8K HDMI) beyond just a few meters

In short, the more performance you need, the more effort and cost it takes to make copper work — and the more you’re fighting your own infrastructure.

Fiber is Built for Modern Systems

Fiber optics solves many of these problems by design — not through workarounds. These are some of the key advantages of fiber:

Protocol agnostic

Fiber links can support HDMI, DisplayPort, Ethernet, MIPI, and other digital signaling without changing the cable medium — just change the optoelectronics at the end-points.

Lower power consumption

Fiber easily carries multi-gigabit signals over 10s to 100s of meters with no repeaters or signal boosters required for reduced power consumption and easier thermal management.

Immunity to EMI

Because fiber uses light instead of electricity, it’s completely immune to electromagnetic interference — ideal for operating rooms, industrial plants, and aircraft.

Lightweight and compact

Fiber is far lighter and smaller than a comparable copper bundle, helping reduce overall cable volume and improve routing flexibility, especially in systems with a lot of moving components.

Improved signal integrity

Fiber provides clean signal paths with minimal jitter, no ground potential issues, and no need for impedance matching.

SWaP: Size, Weight, and Power Optimization

In environments where space and weight are constrained — such as surgical booms, airborne systems, or mobile computing platforms — fiber makes a measurable difference.

- Smaller diameter cables mean easier routing through tight spaces or articulated joints

- Lower weight reduces overall system mass, which is critical in aerospace, defense, and mobile robotics

- Fewer active components (like re-timers or signal boosters) reduce power consumption and heat dissipation

- Single-fiber WDM options Inneos even has single fiber optical subsystems that can replace multiple copper links or fiber ribbon cables, further reducing cable complexity

Simplicity at the System Level

Despite common misconceptions, fiber doesn’t have to be complicated. In fact, Inneos builds fiber solutions specifically designed to reduce system complexity:

No configuration: Plug-and-play extenders and embedded modules handle conversion automatically

No special fiber needed: Standard OM3 or OM4 multimode fiber is often sufficient

No multifiber bundles: Inneos WDM solutions can transmit multiple channels over a single fiber

No compression: Uncompressed video means no latency or loss of image fidelity

The result: a system that’s easier to integrate, more robust in the field, and ready to scale.

Why Now?

Fiber is no longer optional in high-performance systems — it’s essential.

Whether you’re enabling real-time AI inference, designing a factory-wide vision system, or moving uncompressed 4K or 8K video, fiber offers the speed, performance, and reliability your system needs. And with Inneos, you can deploy optical connectivity with the same confidence and ease you expect from copper. Now is the time to rethink your connections, and Inneos is here to help.