Copper vs. Fiber: Choosing the Right Connection for Today’s Systems

As today’s systems demand more signal integrity, more speed, and more reliability, the choice of physical connectivity is no longer just an afterthought — it’s a critical design decision. Whether you’re transmitting high-resolution surgical video, streaming sensor data from airborne platforms, or building AI-enabled industrial systems, your connection can either be the bottleneck — or the breakthrough.

Fiber optics is becoming the preferred choice for a growing range of applications that have outgrown the limitations of copper. From hybrid operating rooms requiring long-reach 4K and 8K video with zero latency, to flight-critical avionics systems where EMI immunity and lightweight cabling are essential, fiber delivers the performance copper simply can’t match.

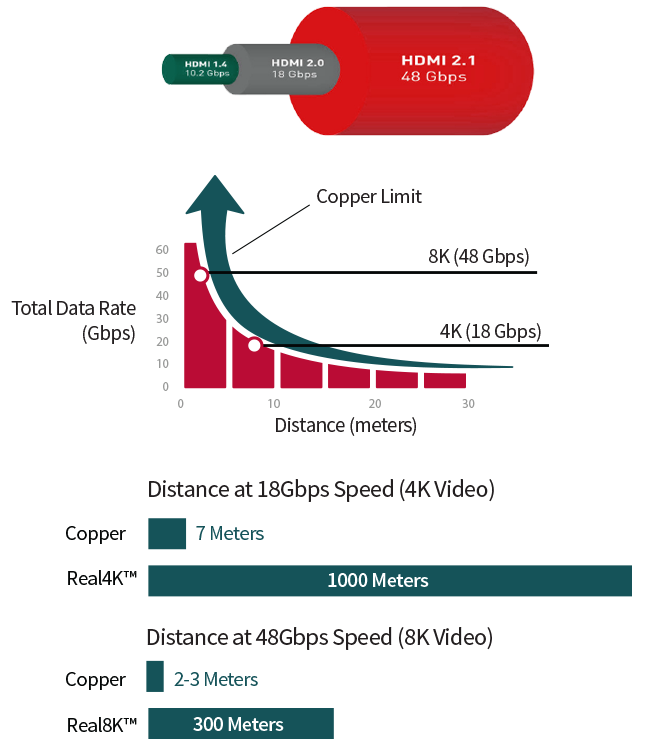

Traditional copper HDMI cables, for example, can carry 4K video (18 Gbps) only 3–5 meters (10–16 feet) before performance drops — and 8K video (up to 48 Gbps) is typically limited to 1–2 meters (3–6 feet) without significant signal degradation. As cable runs get longer or environments become more electrically noisy (such as in operating rooms or aircraft fuselages), signal integrity becomes a real concern. Boosters, shielding, and active copper cables can help, but they add bulk, cost, and complexity.

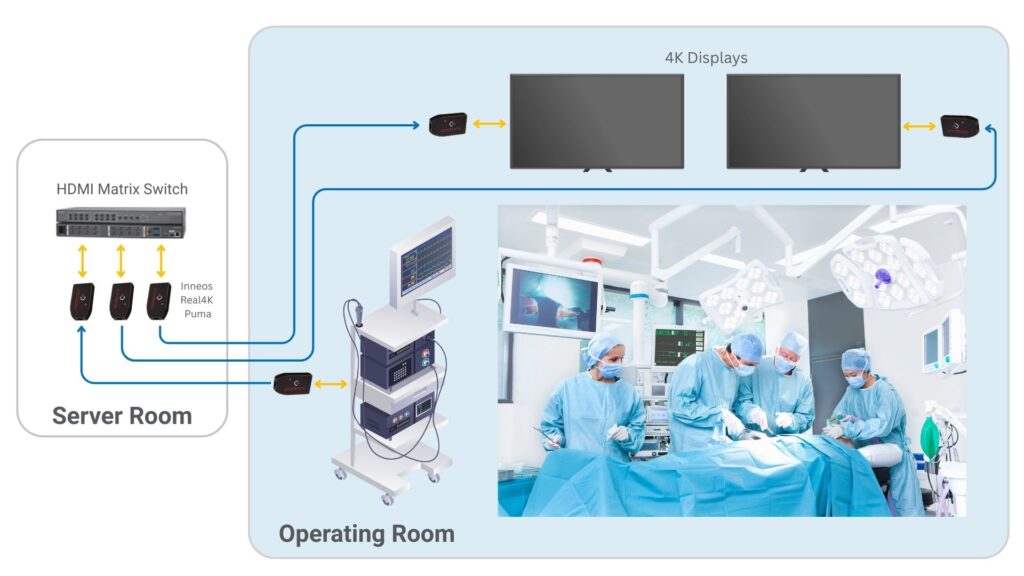

Fiber solves these problems. It delivers much higher bandwidth, can transmit clean signals over long distances (100+ meters), and is inherently immune to electromagnetic interference. It’s also smaller and lighter than copper — a major advantage for space-constrained designs or mobile systems. For medical applications, fiber enables surgical teams to position equipment and displays flexibly around the OR without sacrificing resolution or introducing latency. In aerospace systems, fiber reduces weight and eliminates signal issues caused by EMI from motors, power systems, or radar. To take advantage of fiber connectivity, the system simply needs to add electrical-to-optical converters for the system protocol — no need to redesign the whole system or change communication protocols.

Copper is Hitting Its Limits

Copper interconnects are simple, familiar, and effective — but only up to a point. As data rates increase and system footprints shrink, copper struggles to keep up:

- EMI susceptibility means copper often requires shielding, isolation, or re-clocking to preserve signal integrity

- Crosstalk and ground loops can introduce intermittent or hard-to-trace failures

- Cable bulk and weight increase quickly with speed and shielding requirements

- Signal degradation over distance makes it difficult to support high-resolution video (like 4K or 8K HDMI) beyond just a few meters

In short, the more performance you need, the more effort and cost it takes to make copper work — and the more you’re fighting your own infrastructure.

WDM Takes Fiber Even Further

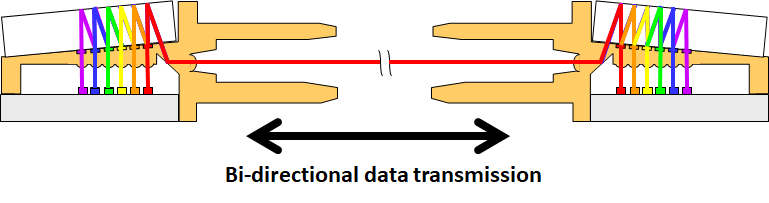

Standard fiber optics typically use a single wavelength of light to carry one data stream down the fiber. That alone is a major upgrade from copper. But what if you could send multiple data streams — independently and simultaneously — over that same fiber?

That’s exactly what Wavelength Division Multiplexing (WDM) enables. With WDM, different wavelengths (or “colors” of light) carry separate channels of data over a single strand of fiber. This means that instead of using multiple fibers or bulky multifiber cables, you can transmit multiple high-speed signals down one ruggedized link — simplifying the system and multiplying its capacity.

For example, in a surgical environment, WDM can carry multiple 4K video streams, control signals, or diagnostic data over a single fiber routed through a boom or wall — no bundling, no compression, no delay. In aerospace, a WDM-enabled fiber link can aggregate mission-critical sensor data, command and control links, or timing signals into one EMI-immune fiber path that’s easier to manage, easier to route, and far less prone to noise or degradation.

Historically, WDM has been seen as a complex and expensive solution reserved for telecom infrastructure. But Inneos has reimagined it for embedded and application-specific environments. Our WDM optical engines and extenders handle all the internal optics, conversion, and alignment — meaning you don’t need to be a photonics expert to use them. You just plug it in and it works.

The Inneos Advantage: Fiber and WDM Made Simple

We believe fiber should be as easy to integrate as any other interconnect. That’s why our solutions are designed to fit into real-world systems with standard connectors, compact footprints, and built-in performance. Whether you’re using an external Real4K™ HDMI extender or an embedded WDM optical engine, we provide the building blocks to make your system lighter, faster, and more reliable — without adding unnecessary complexity.

Fiber is no longer just an alternative to copper — it’s the path forward. And with WDM, it’s also a path to scale, enabling your system to grow without rewiring or repackaging.

Let’s Build a Better Connection

Still using copper for critical connections? It may be time to re-evaluate. Whether you’re transmitting video, data, or control signals, fiber offers a reliable, high-performance, and future-proof solution. Want help deciding if fiber is right for your application? We’re here to help.