Machine vision systems are the eyes of modern manufacturing, enabling everything from quality control to robotic guidance. As these systems become more sophisticated and manufacturing environments more demanding, the traditional copper-based connectivity solutions are hitting their limits. Enter MIPI (Mobile Industry Processor Interface) over optical fiber – a game-changing approach that’s transforming how we think about industrial imaging connectivity.

Understanding the Machine Vision Interface Landscape

To appreciate why MIPI over fiber is revolutionary, it’s important to understand where MIPI fits in the machine vision connectivity ecosystem and how it differs from traditional approaches.

Traditional Interface Architecture

In conventional machine vision systems, the imaging pipeline typically looks like this:

CMOS Sensor → Camera Processing/FPGA → Interface Conversion → Cable → Frame Grabber/Host

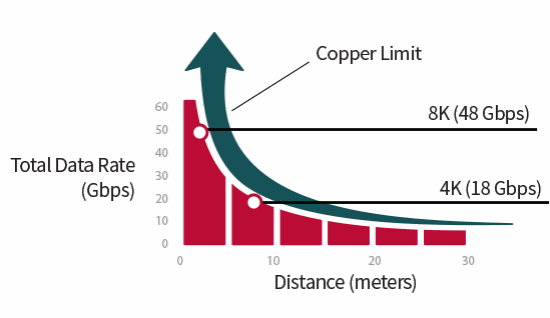

Most industrial cameras use MIPI CSI-2 (Camera Serial Interface) internally to transfer raw image data from the CMOS sensor to the camera’s processing unit. However, because copper cabling cannot transfer this data more than a few meters, this MIPI signal is then converted to industry-standard interfaces:

- Camera Link: Parallel interface supporting up to 6.8 Gbps, widely used in high-speed applications

- GigE Vision: Ethernet-based standard supporting 1-10+ Gbps, popular for its networking capabilities

- USB3 Vision: USB-based interface supporting up to 5 Gbps, common in compact systems

- CoaXPress: Coaxial cable interface supporting up to 12.5 Gbps, gaining traction in high-bandwidth applications

The MIPI Revolution: Eliminating Conversion Overhead

MIPI over fiber represents a fundamental architectural shift. Instead of converting the native MIPI signal from the sensor, the system extends the MIPI interface directly over optical fiber for distances of 1000 meters:

CMOS Sensor → MIPI CSI over Fiber → Direct Processing

This approach eliminates multiple conversion stages, reducing latency, power consumption, and system cost and complexity while maintaining the sensor’s native timing and control characteristics.

The Copper Conundrum in Industrial Environments

Traditional machine vision systems using Camera Link, GigE Vision, or USB interfaces face significant challenges in modern manufacturing environments:

Distance Limitations: Copper cables experience signal degradation over distance. Most copper-based machine vision interfaces are limited to cable runs of 10-100 meters before requiring expensive repeaters or signal boosters. In large manufacturing facilities, this constraint can be crippling.

Electromagnetic Interference (EMI): Manufacturing floors are electrically noisy environments filled with motors, power supplies, switches, sensors, high-power equipment, etc. Copper cables act as antennas, picking up electromagnetic interference that can corrupt image data or cause system instability.

Weight and Flexibility: High-quality copper cables, especially those capable of carrying high-bandwidth video signals, tend to be thick and heavy. This creates challenges in robotic applications where cable weight affects movement precision and wear.

Why MIPI over Fiber Changes Everything

MIPI CSI (Camera Serial Interface), originally developed for mobile devices to connect camera sensors to application processors, has evolved into a robust standard for high-speed imaging applications. The key insight is that virtually all modern CMOS image sensors already speak MIPI natively – it’s the universal language between sensors and processors.

Traditional machine vision architectures force an unnecessary conversion: sensor data travels via MIPI a short distance to a camera’s internal processor, gets converted to Camera Link/GigE/USB, then travels over copper cable for a longer distance, then often gets converted back to a format the host processor can understand. Each conversion introduces latency, power consumption, and potential signal integrity issues.

MIPI over fiber eliminates this conversion overhead entirely. When combined with optical fiber transmission, it addresses every major limitation of copper-based systems while introducing compelling new advantages.

Architectural Advantages: Native Sensor Communication

The most profound benefit of MIPI over fiber isn’t just the fiber optic advantages – it’s the elimination of interface conversion overhead:

Reduced Latency: Traditional systems introduce multiple conversion delays. A typical Camera Link system might have 2-5 milliseconds of conversion latency, while MIPI over fiber can achieve sub-millisecond sensor-to-processor communication.

Simplified Timing: MIPI preserves the sensor’s native timing relationships, critical for applications requiring precise synchronization between multiple cameras or sensors.

Enhanced Control: MIPI’s bidirectional nature allows real-time sensor parameter adjustment and advanced features like region-of-interest programming directly from the host processor.

Lower System Cost: Eliminating interface conversion hardware reduces both camera complexity and system cost, especially in multi-camera installations.

Distance: Breaking the Boundaries

Optical fiber fundamentally changes the distance equation. While copper-based MIPI implementations are typically limited to a few meters, fiber-optic connections can easily span 1000 meters without signal degradation. This capability opens up entirely new architectural possibilities:

- Centralized Processing: Camera sensors can be distributed throughout a facility while processing units are consolidated in clean, temperature-controlled environments

- Hazardous Area Deployment: Cameras can operate in explosive or corrosive environments while keeping sensitive electronics safely distant

Immunity to Electromagnetic Interference

Perhaps the most immediately noticeable benefit in industrial environments is fiber’s complete immunity to electromagnetic interference. Optical signals travel as light pulses through glass fibers, making them impervious to the electrical noise that plagues manufacturing environments. This translates to:

- Consistent Image Quality: No mysterious artifacts or intermittent dropouts caused by nearby equipment

- Reliable Operation: Systems maintain performance even in the most electrically challenging environments

- Simplified Installation: No need for careful routing away from power cables or shielded conduits

Power Consumption: The Efficiency Advantage with Fiber

One of the most compelling aspects of MIPI over fiber is its power efficiency profile, which becomes increasingly important as systems scale.

Copper Power Challenges

Traditional copper-based machine vision systems face escalating power consumption as requirements increase:

- Signal Amplification: Longer copper runs require active repeaters or signal boosters, each consuming additional power

- Heat Generation: High-speed copper interfaces generate significant heat, requiring cooling systems that consume even more power

- System Complexity: Multiple power conversion stages reduce overall efficiency

Power Consumption with MIPI over Fiber: Multiple Efficiency Gains

MIPI over fiber implementations show dramatic power savings through several mechanisms:

Elimination of Interface Conversion: Traditional cameras require power-hungry FPGA or ASIC circuits to convert from MIPI to Camera Link/GigE/USB. MIPI over fiber eliminates this conversion entirely.

Elimination of Repeaters: Fiber’s long-distance capability removes the need for power-hungry signal boosters. A system that might require three repeaters over a 300-meter copper run needs none with fiber.

Reduced Heat Generation: Optical transceivers generate minimal heat compared to high-speed copper drivers, reducing cooling requirements and improving reliability.

Simplified Power Architecture: Fewer active components mean fewer power conversion stages and higher overall system efficiency.

The Future of Industrial Machine Vision

As industrial automation continues to evolve, the demands on machine vision systems will only increase. Higher resolutions, faster processing, more complex analysis, and greater integration with AI systems all point toward higher bandwidth and more distributed architectures. MIPI over fiber provides the foundation for these next-generation systems while solving today’s most pressing connectivity challenges. The combination of extended range, electromagnetic immunity, massive bandwidth, and superior power efficiency makes MIPI over fiber a compelling choice for modern manufacturing environments. Inneos’ optical transceivers for MIPI over fiber can enable this next-generation machine vision infrastructure.

The transition from copper to fiber in machine vision isn’t just about solving current problems – it’s about enabling capabilities that weren’t previously possible. From facilitating AI-driven quality control systems that require massive data throughput to enabling new forms of distributed manufacturing intelligence, MIPI over fiber is positioning industrial machine vision for the next decade of innovation.