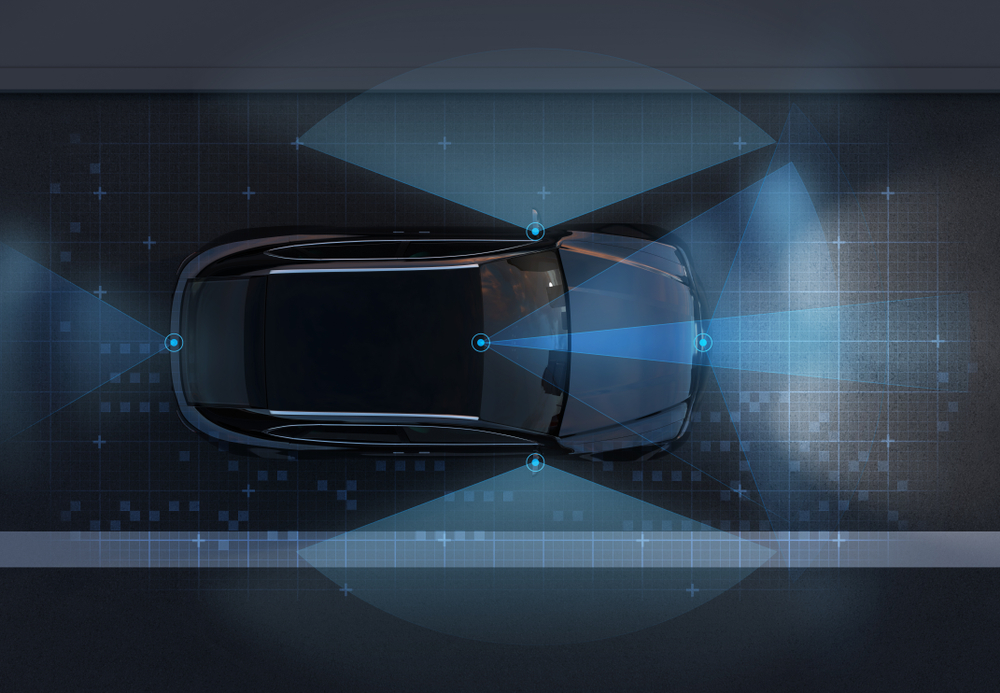

As vehicles shift toward software-defined architectures and autonomous driving, the amount of data moving around inside the car is exploding. Cameras, radar, LIDAR, infotainment, and advanced driver assistance systems all need massive bandwidth with little tolerance for latency. That’s why the industry is now looking to 25G Ethernet links as the backbone of in-vehicle networks.

But there’s a catch: power consumption. In a car, every watt matters. Higher PHY power doesn’t just mean higher operating costs—it means more heat inside compact electronic control units (ECUs), more complex cooling requirements, and greater load on already limited vehicle power budgets (especially in EVs). So how do we connect vehicles at 25G without blowing the power and thermal budget? The answer lies in the choice between copper vs. optical.

Why Power is Such a Big Deal in Cars

Unlike a data center, where you can scale cooling and power delivery at the rack level, vehicles have tight design envelopes. Power for high-speed links must compete with the needs of drive motors, sensors, and all of the modern infotainment and displays of modern vehicles.

Copper PHYs at 25G work hard to overcome insertion loss in automotive-qualified cables. They rely on high-swing transmitters and complex equalization circuits at the receiver. Both of those burn power—and the longer the link, the worse it gets.

Optical links, on the other hand, barely notice the extra distance. A VCSEL transmitter and TIA receiver can deliver clean 25G signals over lightweight fibers with much lower PHY power. Plus, optics are immune to electromagnetic interference (EMI)—a huge benefit in the electrically noisy environment of a car.

Breaking Down the PHY Power at 25G

Here’s where the power goes in a 25G Ethernet PHY:

- SERDES & FEC/CDR: baseline overhead, this is roughly the same for copper and optical.

- TX Driver: grows with distance for copper; flat and low for optical.

- RX Front-End: equalizers in copper burn more power as the channel gets longer; optical TIAs remain approximately constant.

Here’s how the numbers stack up at 10 meters (long enough to span a vehicle backbone) for copper vs. optical:

- Copper PHY (10 m): Requires strong TX swing and heavy equalization. Power per lane: ~2.5–3 W.

- Optical PHY (10 m): Flat power consumption over distance. Power per lane: ~1 W.

That’s at least a 60% decrease in power per lane—and when you multiply across the many high-speed links in a modern in-vehicle network architecture, the system-level power savings become very significant.

Data Center Parallels (and Lessons Learned)

We’ve already seen this story play out in data centers. At 25G, copper DACs are only used for very short reaches (1–2 m). But once links stretch to 3 m and beyond, optical consistently outperforms copper on power, thermals, and manageability. The automotive industry is now hitting the same tipping point.

The difference is that vehicles don’t have the luxury of massive cooling systems or relaxed weight budgets. That makes the case for fiber optics in automotive even stronger.

The Road Ahead

As in-vehicle networks scale upward toward 25G and beyond, the choice between copper and optical won’t just be about bandwidth—it will be about efficiency, reliability, and EMI immunity. Optical Ethernet PHYs offer a clear path to meet tomorrow’s automotive data demands without sacrificing power budgets or thermal limits.